Menu ☰

The Ultimate Guide to Snow Retention Systems

• Why Do Your Need Snow Guards for a Metal Roof?

• Safety

• Liability

• Damage Prevention

• Finding the Right Snow Retention System

• Standing Seam Snow Retention Systems

• Discontinuous Snow Retention for Standing Seam Panels

• Continuous Snow Retention for Standing Seam Panels

• Exposed Fastener Snow Retention Systems

• Exposed Fastener Snow Guards

• Exposed Fastener Rail Systems

• Snow Guard Materials and Quality

• Stainless Steel Snow Guards

• Powder Coated Snow Guards

• Why Not Wet Paint?

• Polycarbonate Snow Guards

• Installing Snow Guards

• How is Snow Retention Calculated?

• Choosing the Right Fasteners for Exposed Fastener Snow Guards

• Choosing the Right Clamps for Clamp Compatible Snow Guards or Rail Systems

• Using the Right Tools

• Get the Right Snow Retention

Why Do You Need Snow Guards for a Metal Roof?

There are three primary reasons why having a good snow retention system on a metal roof is important. Those reasons are safety, liability,

and damage prevention.

Safety

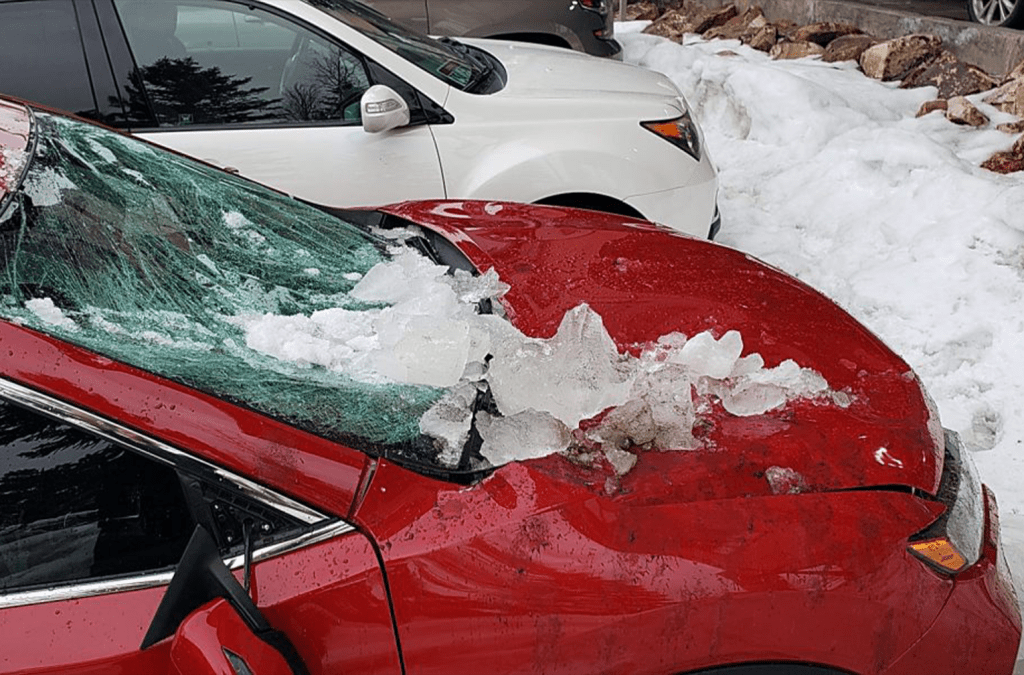

The first reason (and most important!) is safety. Without snow retention, people, pets and landscaping are at risk of snow and ice sliding off of metal roofs in what can be incredibly dangerous avalanches. Gutters can also retain ice dams, which can create dangerous falling ice. These avalanches can harm persons, animals and damage property that is under the roof. Although the snow on a roof doesn’t compare to the amount of snow on the side of a mountain (in case you are wondering if the term “avalanche” is an overstatement), the amount of snow that can fall off of a roof often weighs in the tons. While some roofs may seem relatively small, the amount of snow that can be retained on a roof (and subsequently fall off) is no small matter at all. Every year there are stories in the news of persons who were seriously injured or even killed by falling snow and ice. Having the proper snow retention system installed is potentially a life and death decision, which makes snow retention a must in regions that receive consistent annual snowfall.

Liability

The second reason is in line with safety, and that is the issue of liability. If falling snow and ice does cause injury or damage, that leaves the homeowner or business owner liable for those injuries and damage. No homeowner or business owner wants to put people or property at risk for damage, and so snow retention is important to protect against these risks, and the probability of being held liable should falling snow and ice create a dangerous situation.

Damage Prevention

The third reason why snow retention is necessary for metal roofs is to protect the roof itself from damage. Without snow retention, heavy snow loads can

pull off other components attached to the roof. It isn’t uncommon for pipes, satellite dishes and gutters to be completely torn out of metal panels by heavy

snow loads. When this happens, not only do the parts that were dislodged by the snow need to be replace, but the metal panels where those parts were attached are going to need to be replaced as well. In comparison to what this kind of damage can cost in repairs, a good snow retention system is well

worth the investment.

Not have snow retention can not only cause damage to the metal roof itself, but also to the structure below it. Snow that unevenly builds up in the valleys of metal roofs can cause leaks and structural damage. Properly installed and positioned snow retention systems will insure that snow remains more evenly distributed so as not to overload any one point of the roof.

In addition to the potential for damage to the roof, there is potential for damage to the building structure itself. Snow and ice that falls off of a roof will build up along the sides of the home or building. This can cause damage to siding and other components attached to the sides of a building. Also, as temperatures warm and the snow and ice begins to melt, the amount of snow and ice melting can heavily saturate the area around the building, causing the potential for leaks and can even compromise the integrity of the buildings foundation.

Finding the Right Snow Retention System

Finding the right snow retention system is largely dependent on the type of metal panels being used. The two major panel types are standing seam and exposed fastener.

Standing Seam Snow Retention Systems

Standing seam metal roofs are among the most popular for retail, hospitals and clinics, as well as private homes. There are a few options for standing seam snow retention, all of which fit into the two major categories of snow retention systems which are discontinuous and continuous systems.

Discontinuous Snow Retention for Standing

Seam Panels

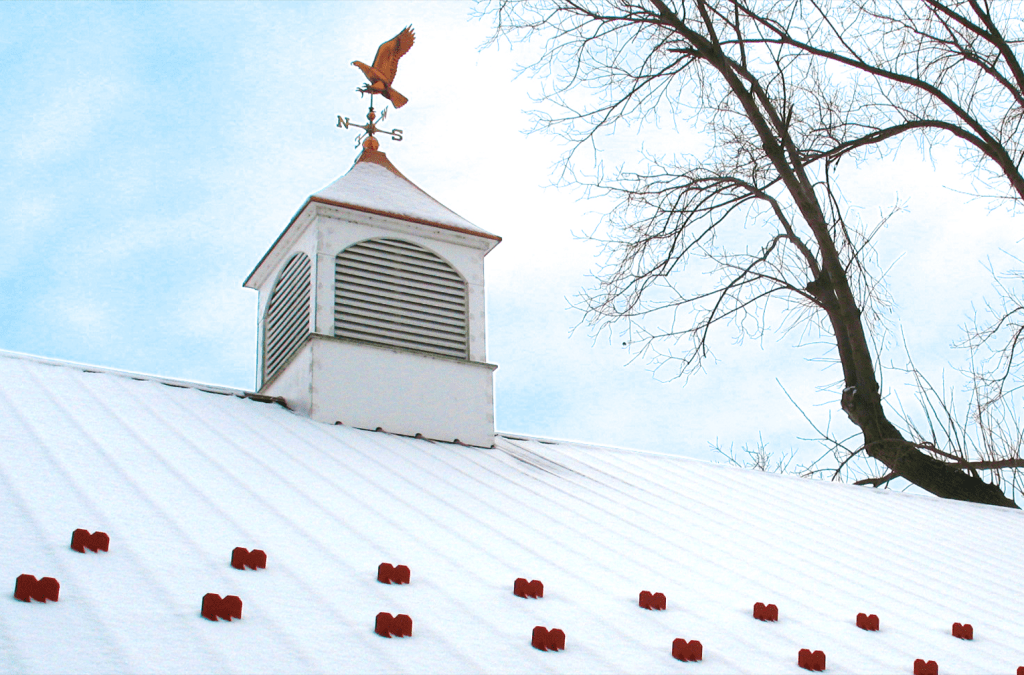

Discontinuous snow retention systems are in short what most would call “snow guards.” These are individual guards that are placed in a staggered pattern along the eave of the metal roof. There are standing seam snow guards that are a single unit (meaning that no additional parts are needed), and there are standing seam snow guards that require additional clamps in order to be attached. Snow guards work in conjunction with each other to form a snow retention system.

Important in choosing the right snow guards for standing seam panels is ensuring the quality of the guards, and that the method of attachment does not damage the panels so as to void the metal roof warranty. Set screws used for attaching snow guards to standing seam profiles should be rounded point set screws, not cup point set screws. Cup point set screws will break the protective coating on metal panels, leaving the area open to the elements and liable to corrosion. Round point set screws will only dimple the panels where the guards are installed, leaving the coating intact and not voiding the metal panel warranty from the manufacturer.

Continuous Snow Retention for Standing Seam Panels

Continuous snow retention systems are also called rail or fence systems. These are typically aluminum rails attached to the purlin above the eave of the metal roof, and are continuous of the length of the roof. The rails for these systems are attached using specialized clamps. There are a large variety of clamps made to fit the differing standing seam profiles which are often specific to the panel manufacturer. Camp manufacturers like S-5! have online tools for searching for the right clamp to fit any given metal panel profile in their system. Finding the right clamp is important. Not only does the clamp need to be the right fit, but since different clamp profiles can vary in cost, having the right clamp for the right profile can save on a metal roofing project.

Exposed Fastener Snow Retention Systems

For exposed fastener panels, the options for snow retention systems are similar to that of standing seam, expect that the attachment method for exposed fastener systems requires penetrating the metal panels with the appropriate metal roofing screws.

Exposed Fastener Snow Guards

When it comes to exposed fastener snow guards, the main point is to ensure that the guard has a sealant at the attachment point, such as an EPDM rubber washer, to ensure that holes made in the panels by fasteners are properly sealed. Protecting the panels from the elements, as well as ensuring that the area is completely weather-proofed is of the utmost importance. Exposed fastener snow guards, like standing seam snow guards, will also be arranged in a staggered pattern along the eave of the metal roof. Use a snow guard calculator such as the one found at snowguards.biz to calculate the number and placement for snow guards

Exposed Fastener Rail Systems

Much like exposed fastener snow guards, the options for rail systems on exposed fastener roofs are also similar aside from the attachment method. Instead of clamps for attaching the rails, there are a variety of bracketing options available for fastening the rail systems to the metal roof.

This drill point is the most common for metal to wood applications because of its ability to drill into some of the hardest wood.

Snow Guard Materials and Quality

Stainless Steel Snow Guards

With a number of options for snow guard materials on the market, the best in quality would be guards made from high grade stainless steel. Stainless steel is resistant to corrosion, making t the metal of choice for anything that is constantly exposed to the elements. Depending on the gauge of the stainless steel, it can also be able to withstand heavy loads, making it a good choice for snow retention. Knowing the grade and gauge of a stainless steel snow guard is important when choosing a stainless steel snow guard.

Powder Coated Snow Guards

When going with a stainless steel snow guard, these can often be powder coated to match the color of the metal panel. However, not all powder coatings are created equal. When purchasing powder coated snow guards, make sure the right kind of powder coating was used for exposure to sunlight and weather. The more durable the powder coating, the longer the snow guards will retain their color, and the steel underneath the coating will remain protected from the elements.

Not only are there varying types of powder coatings, there are also varying methods for applying powder coating. How well a powder coating adheres to a stainless steel now guard will depend on how that snow guard was prepared before it was powder coated. Some manufacturers will simply powder coat stainless steel snow guards right off the assembly line. However, it is important for stainless steel to go through a preparation process before getting powder coated, ensuring maximum adhesion. For maximum adhesion, the surface of stainless steel should be prepared by tumbling in with an abrasive material such as ceramic granules. This results in a textured surface on the snow guard, creating additional surface area for the powder coating to adhere. After being tumbled with an abrasive, the guards go through a bath process to remove any lose particles. After this, the guards are in prime condition for being powder coated.

Why Not Wet Paint?

There are a number of reasons why powder coating is the best route for color matching snow guards, such as the ease of application, durability and environmental friendliness. However, the most important is that powder coating doesn’t just have good adhesion, it also has a good cohesion. Powder coating has the unique ability of actually bonding with the material it is applied to, meaning that powder coating rarely chips off the way wet paint can, and it also has a much higher likelihood of lasting just as long as the snow guard itself.

Polycarbonate Snow Guards

A popular low cost option snow guard is one made of polycarbonate; a highly durable type of plastic. While polycarbonate guards tend to be lower in cost than stainless steel guards, they also tend to be less durable. The pros of polycarbonate guards are that they may be lower in cost, and are “invisible.” These guards are not made to fit standing seams, and so require that use of adhesive and screws in order to attach to any kind of panel profile.

Before going with polycarbonate snow guards, there are a few points to take into consideration. Polycarbonate snow guards, while durable, are not guaranteed to last as long as stainless steel snow guards. This means that there is a chance of the guards failing or needing to be replaced. Polycarbonate is also not as resistant to sunlight and weather as stainless steel. High quality polycarbonate snow guards are made from “virgin” polycarbonate, meaning they are not manufactured from recycled materials. They will also be polycarbonate lexan, meaning they are treated for resisting the yellowing effect that sunlight tends to have on polycarbonate. However, there is no guarantee on how long that may hold up.

Installing polycarbonate snow guards is also something to take in account. Although some installation instructions may only recommend using an adhesive attaching a polycarbonate guard to the surface of a metal panel, the guard is only as strong as the metal panels coating. If a snow load is heavy enough to lift off the coating the metal panel receives to protect it from corrosion, then the adhesive can pull that coating off along with the guard, leaving a portion of the metal panel exposed to corrosive elements. This is why it is recommended that adhesive and fasteners be used for installing polycarbonate snow guards, since a mechanical bond created by fasteners will always outlast an adhesive bond.

Installing Snow Guards

How is Snow Retention Calculated?

The best and easiest way to calculate the necessary number of snow retention devices for a metal roof is to use a snow retention calculator. Levi’s Building Components has developed a snow guard calculator for calculating the number of Snow Defender snow guards needed for any given metal roof profile, and S-5! has developed a calculator for the S-5! rail systems.

These calculators use what is called the tributary force, and compares this to the allowable snow load for a given device. The tributary force is determined by taking into account the snow load for a geographical region, the slope of the metal roof and the length of the roof. This number essentially gives the potential force that a snow retention system may be up against. Dividing this force into the allowable load for each device, the length of the roof and the spacing between panel ribs will provide the number of devices needed per panel. The Levi’s Building Components Snow Defender calculator will slightly overestimate the number of guards needed as an additional safety measure. This additional safety measure is important, because the snow load for a given region is based on the average snow fall for the area, but snow fall can always exceed the average.

Choosing the Right Fasteners for Exposed Fastener Snow Guards

When it comes to exposed fastener snow guards, choosing the right fasteners is just as important as putting the right number of guards and having the correct placement. The reason for this that the quality and size of the screw is going to determine what is known as the pullout strength, which is the amount of force it takes to lift a fastener out of the metal panels and purlins to which they are fastened. The screw size (usually ranging from #9-#14), and also the thread type is what effects pullout strength. The larger the screw (#12’s or #14’s) the greater the pullout strength. For this reason, when it comes to holding snow guards in place as those guards retain heavy loads of snow, it is recommended that the larger size screws are used. It is important to remember that the strength of snow retention system is first and foremost dependent on the strength of the mechanical bond that system has to the metal roof. For standing seam, the set screws create that bond. For exposed fastener, it is the fasteners that create the mechanical bond.

Choosing the Right Clamps

When setting up a standing seam snow retention system that requires clamps, making sure the right clamps are used cannot be overstated. There are a variety of clamps available for the differing types of standing seam panels making it likely that there exists a clamp to match a given panel profile. Finding the right one doesn’t have to be challenging, as long as the right information is provided. Knowing the exact manufacturer and panel type that is being used is essentially all that is need to find the right clamps. With the manufacturer name and panel type, clamp manufacturers such as S-5! will easily be able to determine the right clamp. Clamps should not need to be forced to fit any profile, and set screws should be able to secure the clamp tightly.

Using the Right Tools

For installing snow retention systems on standing seam, whether it be for a single snow retention device with its own set screws, or for clamps, the best tool to use is a torque wrench. This will allow for easily reaching the recommended inch pounds for the set screws. It is important to abide by manufacturer recommendations for inch pounds since failing to do so can void warranties, and result in system failures that can cause extensive damage to a metal roof.

The main tool needed for installing a snow retention system on an exposed fastener roof is a drill drive. Many contractors will use impact drivers for installing snow retention systems, but these tend to have too much torque and can cause damage to fasteners, or result in over-driving, which can over-expand the EPDM washer, or even cause the fastener itself to break.