Menu ☰

What to Know About Exposed Fastener Metal Roofing Screws

What are they and what are they made of?

Metal roofing or metal panel screws are specially made fasteners for use in installing metal roof panels. The kind of screw needed varies depending on the panel type. For this article we’re going to focus on exposed fastener metal panels. These screws are typically made from a carbon steel or stainless steel. There is a wide variety of screw types for exposed fastener panels, each having unique features such as a variety of available drill points, corrosion resistant coatings, bonded or non-bonded EPDM rubber washers, different shank diameters, and different thread patterns.

Resisting the Elements: Corrosion Proofing Your Metal Roof

It’s important to make sure the right fastener is used or it may not perform well and may be susceptible to corrosion which can compromise the metal panels. Depending on the region and environmental factors, the use of specialty corrosion resistant screws may be necessary.

Cap Screws

Corrosion resistant cap screws, like the Levi’s ProZ and ProCap are specialty screws that use a carbon steel shank with either a zinc aluminum alloy or stainless steel cap. As a result the exposed portion of the fastener has high corrosion resistance. The benefit of these screws is that in utilizing a carbon steel shank they are able to penetrate metal panels without the need for pre-drilling, while also offering corrosion resistance comparable to 300 series stainless steel screws.

Stainless Steel Screws

300 series stainless steel screws, like the Levi’s Fastgrip #9 SS have the highest level of corrosion resistance. In regions with highly corrosive environment factors such as the high salt content in the air typical of coastal regions, stainless steel screws are often recommended. The main difficulty with stainless steel screws is that they cannot penetrate metal roofing

panels, which means the use of stainless steel screws for metal roofing requires pre-drilling.

EPDM Washers

Another feature of exposed fastener metal panel screws is the inclusion of a rubber washer. The two common rubbers used for these washers are neoprene and EPDM. While neoprene is durable under certain circumstances, EPDM is rated higher for weather resistance. UV exposure is a primary cause of washer degradation, and while every rubber and plastic will experience some level of degradation from UV exposure, EPDM rates highest for its ability to hold up.

Some fasteners utilize a bonded washer, which means that the rubber washer is attached to an aluminum or a galvanized washer. Other fasteners, like cap screws, have non-bonded washers. Zinc aluminum alloy or stainless steel cap screws tend to use a non-bonded washer, but the cap often has a recess that the washer fits into. This allows for the rubber washer to be completely covered by the cap once drilled down. This feature of cap screws is considered by many to have a more aesthetic look than bonded washer screws, and so for many forward facing business and residential applications may go with a cap screw for appearance purposes.

Whether or not a bonded washer or a cap screw should be used are dependent on the application purpose and the level of exposure to harsh elements. EPDM washers do have the potential to degrade over time under harsh conditions. In a region with higher UV exposure as well as other corrosive factors such as air salinity, it is always better to use a screw that completely covers the washer. While these screws tend to be slightly more expensive than bonded washer screws, it would be far more expensive to have to go back and replace screws later as a result of degrading washer.

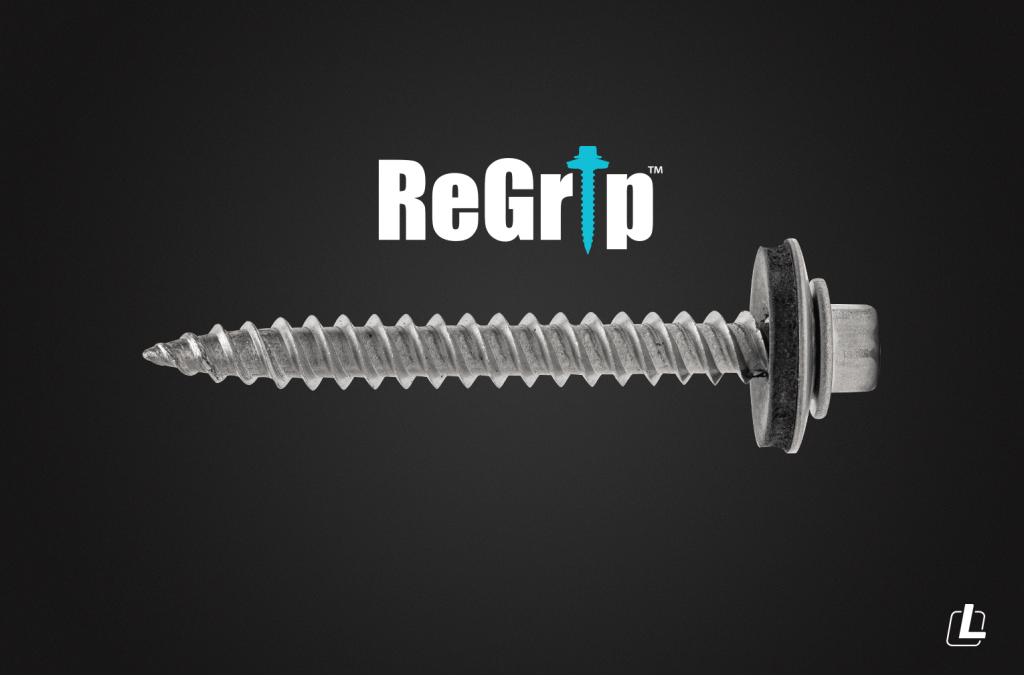

Replacement Screws

Replacement screws were initially used for replacing failing nails used to install metal roofing. Since the use of screws has become the industry standard, replacement screws serve a number of purposes outside of simply replacing failing nails. These screws have a #12 shank with a bonded washer. Most utilize a 1/2″ bonded washer, but some, like the Levi’s Regrip, use the larger 5/8″ washer for better coverage and corrosion protection. These screws can be used for installing metal panels or attaching accessories like snow retention.

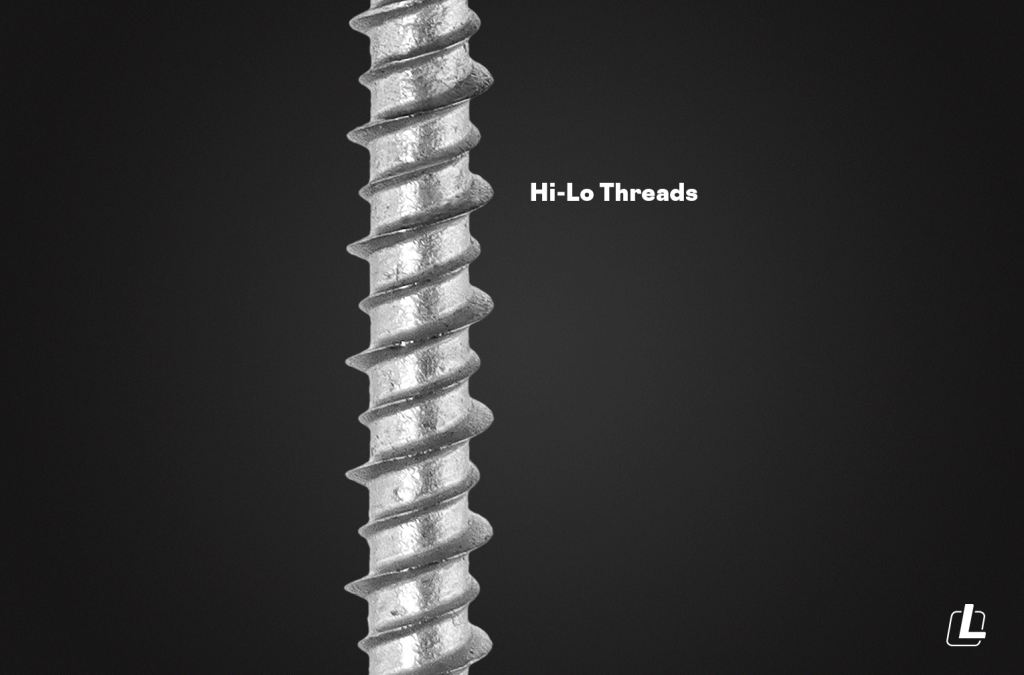

Hi-Lo Thread Screws

Hi-Lo threads are commonly found on screws used for metal to wood installations. The hi-thread creates a deeper cut into the substrate while the low thread reduces the amount of material being displace. The end result is a reduction in necessary driving torque, improved pull-out strength and reduction in the risk of cracking.

Drill Points

Metal roofing screws come with a variety of drill points. The reason for this is because metal roofing is used in both metal to wood and metal to metal construction. For metal to wood construction, a drill point with the capability of going through a metal panel will be good enough. In metal to metal construction however, a drill point with the ability to go through a metal panel as well as a metal beam will be necessary.

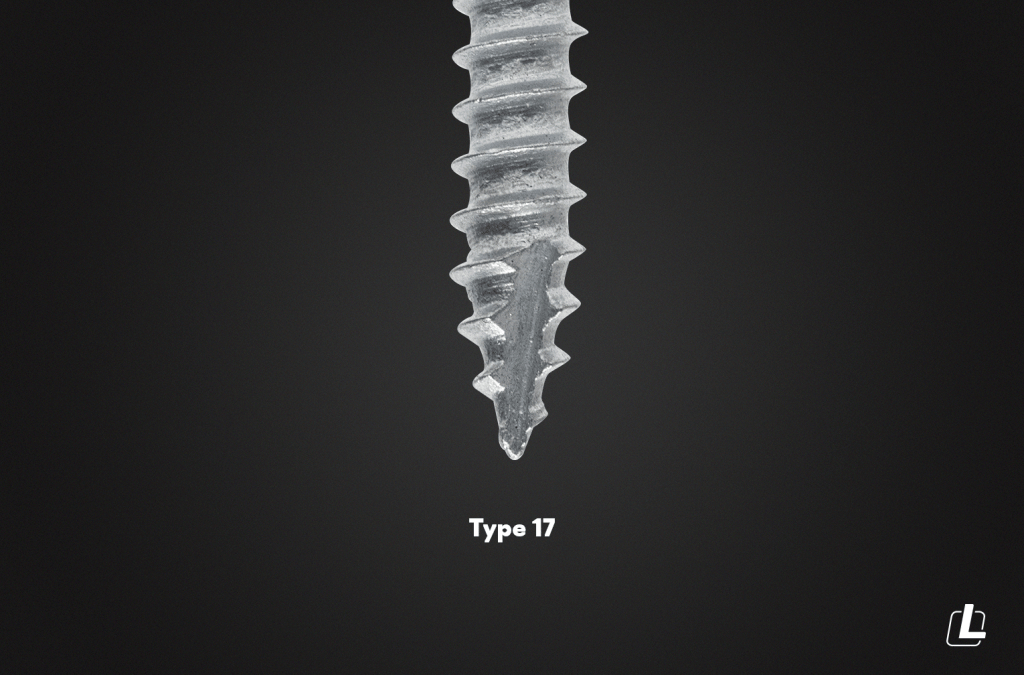

Type 17

This drill point is the most common for metal to wood applications because of its ability to drill into some of the hardest wood.

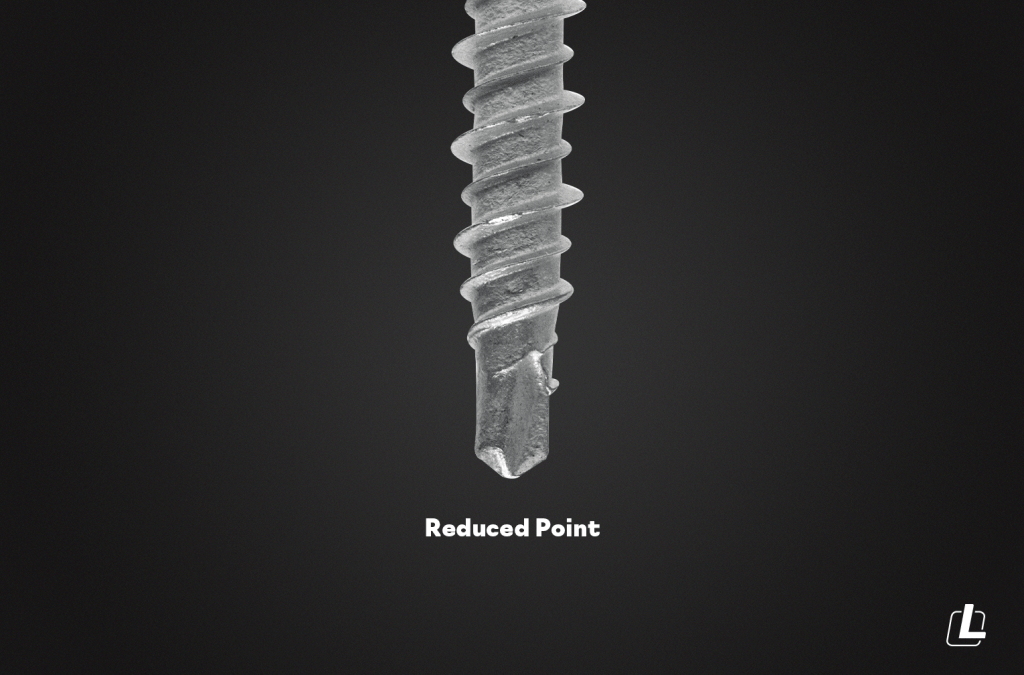

Reduced Point

This is a #1 self-drilling point. Many contractors prefer this point for metal to wood applications because it offers faster start times and also reduces the amount of steel shavings that get trapped

under the washer.

Sharp Point

This is also known as a “type A point.” Stainless steel screws are among the most common with this kind of point, which require pre-drilling before they can be installed.

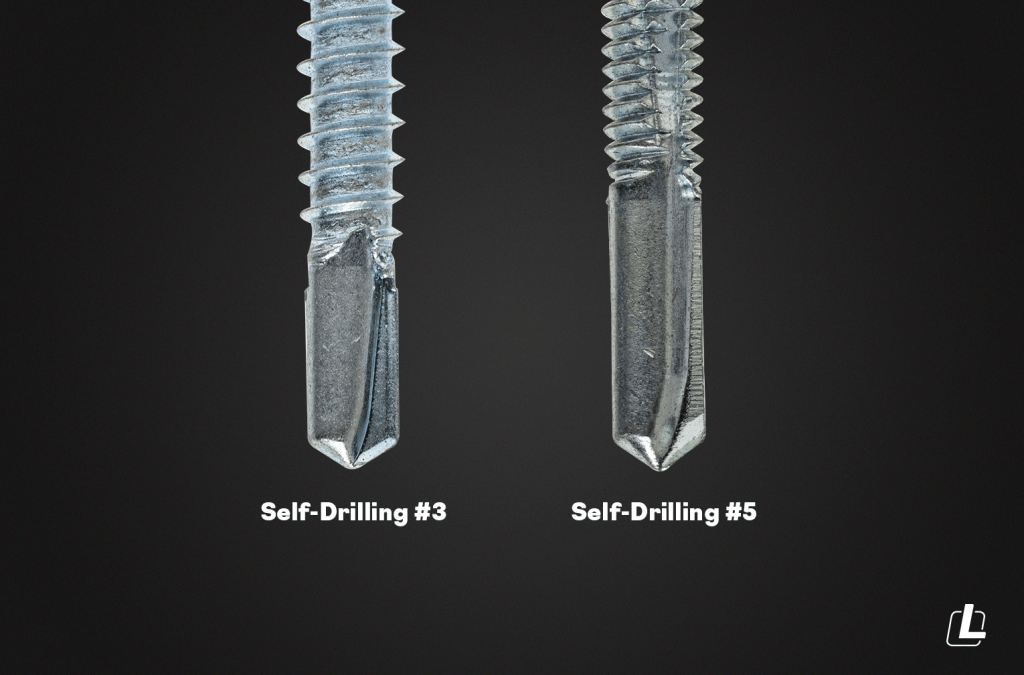

Self-Drilling #3 & #5

These drill points enable metal to metal fastening without the need for pre-drilling. When it comes to metal roofing, #3 and #5 self-drilling screws are the most common for metal to metal application. It is important to use the correct size

drill point depending on the metal gauge. A #3 drill point is capable of drilling through streel with up to 0.210 thickness, while a #5 can

drill through steel with up to

0.500 thickness.